OFF THE WIRE

http://www.ridersforjustice.com/Articles/helmets.pdf

ABSTRACT

This paper reports the results of a legal analysis of mandatory helmet-use legislation. The status of

headgear laws at the federal level and in each of the states was determined, and court decisions

involving challenges to their constitutionality were collected and analyzed.

Helmet-use statutes were first passed by states in 1966. Enactment of such legislation was required of all states the following year; this was the result of a U.S. Department of Transportation regulation

including headgear legislation in its mandatory safety program standards.

During the decade immediately following the promulgation of the Department of Transportation

regulation requiring states to pass mandatory helmet-use statutes, opponents of those laws challenged their constitutionality in court. With a single exception, every state court of last resort that considered the issue upheld motorcycle helmet legislation as constitutional. A large majority of the lower courts that considered the issue likewise upheld their constitutionality.

Despite the overwhelming weight of judicial authority upholding headgear laws as a reasonable means of promoting the public interest, courts disagreed as to what that public interest was. Some courts stressed the welfare and unemployment payments as well as other social costs that would be reduced by helmet-use legislation. Other courts, however, chose to rely on a more direct public benefit--namely, the prevention of multivehicle crashes that could result from an unhelmeted motorcyclist being struck by a flying object and losing control of his vehicle.

Courts also considered a variety of other challenges--both substantive and procedural--to headgear

legislation, and uniformly upheld the legislation against those claims.

In 1976, Congress passed legislation specifically prohibiting the Department of Transportation from

withholding highway-safety appropriations from states that did not require motorcyclists and passengers aged eighteen and over to wear helmets. Since passage of that provision, some thirty states have repealed entirely or weakened their helmet legislation, and bills dealing with motorcycle headgear are being considered by legislatures in a number of other states. On the other hand, efforts to reinstate or strengthen helmet laws have been reported in states that earlier repealed or limited them.

Arguments cited by legislative opponents of helmet legislation include many of those that were raised earlier, without success, in the courts. Those arguments--chief of which is that government should not protect an individual from the consequences of his own folly--possess social and political force; therefore, proponents of mandatory helmet-use legislation must be prepared to face them in the future. Future research into mandatory helmet-use laws should include continued analysis of legislative action on them; it should also attempt to determine the factors that influence legislators' decisions to retain, weaken, or strengthen these laws.

Whether states and municipalities may require motorcycle operators and passengers to wear protective headgear is an issue currently being debated in a number of state legislatures. The states have again become the arena of this debate following congressional passage in 1976 of a provision in the Federal Highway Act, which curbed the power of the U.S. Department of Transportation (DOT) to penalize states that did not enact mandatory headgear legislation. States still may, however, be subjected to penalties for not requiring persons under the age of eighteen to wear helmets.

Prior to the passage of the 1976 provision, the principal method of attacking headgear legislation was to challenge their constitutionality in court. Opponents' arguments typically began with an assertion that helmet-use statutes were designed solely to protect cyclists from themselves, not to protect other

members of the driving public. This being the case, the opponents urged. the state or municipality that enacted them had acted beyond the limits of its constitutional powers.

Constitutional challenges to headgear legislation raised the legal, political, and philosophical question of whether, and to what extent, government may act to protect individuals from their own indiscretions.

Some courts squarely faced this question and held that government may protect human life for its own sake.

Most other courts, however, reached this result less directly by painstakingly describing the social benefits that result from enforced self-protection. Thus the great weight of judicial authority has concluded that motorcycle helmet-use laws, despite their self-protective aspects, were constitutionally permissible: these statutes were within the scope of legislative power; and the opponents' arguments were matters for the legislature--not the courts--to consider.

Even though the constitutional arguments raised by opponents of mandatory headgear legislation carried little weight as constitutional claims, they do have considerable social and political force that has led to the repeal or weakening of headgear legislation by a majority of state legislatures. Arguments that fail to impress a court often will succeed in the legislature; thus, despite the absence of court challenges to helmet laws in recent years, the issues discussed here remain pertinent to the promotion of motorcycle safety. Proponents of mandatory helmet-use legislation, and other safety measures, will continue to face arguments similar to those raised in the cases discussed here.

BACKGROUND

The first mandatory headgear statute was passed by the New York legislature in 1966. The New York statute, forbidding any person from operating or riding on a motorcycle on the public streets or highways without wearing an approved protective device, served as the model for most other states' laws. Massachusetts and Michigan soon followed New York's lead and enacted similar legislation.

That same year Congress passed the Highway Safety Act of 1966, which required states to develop

and implement highway programs approved by, and in accordance with standards promulgated by, the Secretary of Transportation. One of those standards, promulgated by the Secretary in June 1967, required states to enact mandatory helmet-use statutes. Failure to comply could subject states to the loss of federal highway safety appropriations. All but three states eventually complied with the federal standard:

California never adopted headgear legislation; Illinois' statute was declared unconstitutional and was repealed shortly thereafter; and Utah's provision applied only to roads with a posted speed

limit of more than 56 km/h (35 mph).

Following attempts by DOT to penalize the three noncomplying states, as well as efforts by

motorcyclists' organizations to modify the motorcycle standard, Congress added to the Federal

Highway Act of 1976 a provision that limited DOT's penalty powers. As of December 1979 eight

states have repealed their helmet-use laws entirely, and twenty others have limited their mandatory helmet-use statutes to minors. Most of this legislative activity occurred shortly after the DOT motorcycle standard was limited by Congress. In the past year fifteen states considered bills that would repeal existing headgear legislation or require their use by minors only, and only one was passed; efforts to reinstate or strengthen helmet-use laws were reported in seventeen other states, and only one was successful.

During the time the DOT helmet standard was in effect challenges to the constitutionality of headgear legislation were raised in the appellate courts of thirty-four states. Only the Supreme Court of Illinois struck down the state helmet-use statute; the highest courts in twenty-six other states and intermediate appellate courts in seven others upheld such laws against constitutional challenges. The last reported helmet-law cases were decided in 1977.

LEGAL BASIS FOR HEADGEAR LEGISLATION

Headgear legislation is an exercise of a state's "police power," that is, the power to enact laws to

promote the public health, safety, morals, or welfare. While the bounds of the police power are not

capable of precise definition, that power may constitutionally be exercised, even to the point of

interference with personal rights, provided two requirements are met:

• The public interest, not the interests of a particular person or group, requires interference with

individual rights; and

• The means of carrying out the public interest are both reasonably necessary to accomplish it,

and are not unduly oppressive upon individuals.

Since the validity of the police power depends on the existence of both a valid purpose and reasonable means for carrying it out, constitutional attacks on its exercise turn on challenges to the existence of either or both of them.

Most court challenges to helmet laws alleged that they lacked a public purpose, since they dealt only with an individual's private welfare and not that of society as a whole. Such legislation, argued the opponents, was an unjustified infringement of personal liberty.

At the outset, two other considerations strengthen the case for the constitutionality of headgear

legislation. The first is the general presumption of constitutionality that courts give actions of the

legislature. The second is the state's plenary (complete) power over its highways, to regulate for the safety and the best interests of the public.

"Public Charges" and Indirect Public Benefits

The constitutionality of headgear laws depends on the existence of a "public purpose" to support them.

The public purpose furthered by this legislation, as defined by the courts, has ranged from the indirect public benefits of protecting an individual motorcyclist from the consequences of his own dangerous conduct to the protection of all highway users who are exposed to the hazards presented by unprotected cyclists.

Few courts chose to regard the protection of a motorcyclist's life and health as an end in itself.

Instead, many courts pointed to the indirect public benefits flowing from the lower casualty rates among helmeted cyclists: when a person neglects his own health, safety, or welfare, all of society suffers. Many indirect public benefits of helmet-use laws are financial: lost productivity, higher welfare costs, and increased insurance rates. The most frequently quoted expression of this so-called "public charge" rationale is found in a federal district court decision, Simon v. Sargent:

"From the moment of the injury, society picks the person up off the highway; delivers him with

unemployment compensation if, after recovery, he cannot replace his lost job, and, if the injury

causes permanent disability, may assume the responsibility for his and his family's continued

subsistence. We do not understand a state of mind that permits [the motorcyclist] to think that

only he himself is concerned."

Variations of the public-charge rationale for self-protective legislation include: the state's interest in

maintaining a productive citizenry; the effect of motorcycle accidents on insurance rates, particularly in "no-fault" states; the value of helmet use in mitigating damages in civil suits; the strong public policy against self-destruction, making illegal, for example, suicide pacts and self-maiming; and the characterization of the increased motorcycle casualty rate as a "public disaster" requiring action by

society.

A few courts and judges, however, refused to find a public benefit flowing from helmet-use statutes and concluded that those laws were an unjustified invasion of personal freedom. Typical of this "no public purpose" reasoning was made by the Supreme Court of Illinois in People v. Fries:

"However, the legislature may not, of course, under the guise of protecting the public interest,

interfere with private rights...The manifest function of the headgear requirement in issue is to

safeguard the person wearing it--whether it is the operator or a passenger--from head injuries.

Such a laudable purpose, however, cannot justify the regulation of what is essentially a matter

of personal safety."

The dissenters in several other decisions also argued that helmet laws were an imposition of government authority into areas of private conduct and not a proper function of government.

Even those courts that adopted one version or another of the public-charge theory frequently made it clear that not all self-protective legislation would be upheld. Some courts accepted the headgear

requirement, but carefully limited their rulings to the helmet laws themselves and reserved the option to strike down in the future more restrictive safety measures, for example, mandatory seatbelt-use laws.

Some courts used a balancing test to sustain the challenged headgear legislation, such as the version spelled out by the Supreme Court of Hawaii which, in State v. Cotton, articulated its theory of "significant secondary harms":

"Viewed without limit, of course, "secondary harm" arguments could justify an impermissible

wide range of governmental interference with private liberties...[H]owever...merely because

protecting the public from secondary harms could logically justify a vast range of governmental

interferences with individual liberty, and merely because we could define secondary harms as

including anything lessening the full development of an individual's perfection, this does not mean

that such interference is always improper."

Then, after noting the relationship between headgear legislation and reduction of injuries to cyclists, the Hawaii court observed:

"With the great danger of primary harm helmetless cyclists as well as the rationality of helmet

wearing as a safeguard thus statistically supported, the magnitude of secondary harms of the

nature indicated above is sufficiently great to justify the law at issue in this case. In answer to the

reductio ad absurdum argument of the dissent in this case with respect to the extent of

governmental intrusions justifiable by secondary harm analysis, we refer to the statement (in an

earlier decision that upheld the state helmet law as constitutional) that "this holding is limited to

this case."

Similarly, the Michigan court concluded that headgear legislation placed a relatively minor burden upon cyclists while benefitting both cyclists as a class and society as a whole.

Direct Public Benefits

Rather than construct social benefits from enforced self-protection of motorcyclists, many courts have chosen to characterize the public benefit of mandatory helmet-use laws as preventing direct harm to other drivers. A typical judicial statement of this rationale is as follows.

"[N]ot all highways are deserted these days; in fact, few are. If the loss of cyclist control were

to occur on a well-traveled highway the separation between consequence and incidence is less

sharp. Anything that might cause a driver to lose control may well tragically affect another

driver. If the loss of cyclist control occurs on a crowded freeway with its fast-moving traffic, the

veering of a cyclist from its path of travel may pile up a half-dozen vehicles."

A variation of this "direct-harm" theory involved protecting other drivers from additional criminal or civil liability should they be at fault and strike a motorcyclist. One court described this as follows:

"For example, the (helmet law) benefits the driver of a vehicle which may accidentally collide

with a motorcyclist. Since the helmet is designed to reduce injury to the cyclist, it also has a

concomitant effect on the status of the automobile driver. If the helmet succeeds in mitigating

what would otherwise be a fatal injury, then not only has the cyclist survived, but the automobile

driver has not killed anyone."

Relatively few crashes and casualties result from the series of events described above; however, a

direct-harm collision is possible and thus most courts will accept this rationale as sufficient justification for headgear legislation. In addition, because avoiding direct harm is a more narrow legal principle than that of reducing indirect social hams, many courts have preferred it as the reason for holding helmet-use laws constitutional. Even some courts that appeared to endorse the indirect aspects of self-protection as a valid basis for legislation nonetheless preferred to base their holding on the direct-harm rationale.

Other Attacks on Headgear Legislation

Challenges alleging infringement of personal liberty or arguing that the state went beyond its police powers were almost uniformly rejected by courts. Therefore, opponents of headgear legislation either shifted their attack from the purpose furthered by headgear legislation to the means furthering that purpose, or raised other constitutional objections to helmet-use laws. A variety of challenges were raised to helmet-use statutes; here again, nearly all were turned down by state courts. These challenges have included:

• Denial of equal protection, alleging that cyclists have unreasonably been placed in a class

separate from other traffic and drivers, and unjustly regulated on the basis of that distinction.

Courts rejecting equal-protection challenges have pointed out the physical characteristics of

motorcycles, the use to which cycles are typically put, and the increased accident exposure of

cycles as justifications for classification and treatment different from automobiles and trucks.

• Vagueness, alleging that the standards for helmet use failed to give motorcyclists fair notice as

to what type of headgear would comply with the statute. The courts responded by determining

the term "helmet" to have a specific meaning when applied to motorcycle headgear, just as it

does in the case of fire, police, and football helmets.

• Abridgement of freedom of speech, alleging that headgear legislation restricts the cyclist's

freedom to express an idea. The courts have pointed out that helmetless operation of a

motorcycle has a predominant "non-speech" component--namely, conduct that may be

regulated by the police powers of the state.

• Illegal delegation of powers, alleging that the legislature, by giving an administrative body

power to establish headgear standards, unlawfully permitted it to act as a legislative body.

Courts have concluded that headgear legislation is a lawful delegation of power provided it

describes the job to be done, who must do it, and the scope of his authority.

• Infringement of the right to travel, alleging that headgear legislation is an unwarranted

interference with that right. Courts have emphasized that helmet-use statutes merely regulate

and do not prohibit travel. The courts have similarly rejected contentions that headgear

legislation unfairly burdens interstate commerce, declaring that compliance with such laws is a

slight burden.

• Privacy, alleging that headgear legislation violates the motorcyclist's constitutional "right to be

let alone." Courts that have been faced with privacy claims have been inhospitable toward

them. Typical of these was the Wisconsin court in Bisenius v. Karns, which stated: "There is no

place where any such right to be let alone would be less assertable than on a modern highway

with cars, trucks, busses and cycles whizzing by at sixty or seventh miles an hour. When one

ventures onto the highway, he must be expected and required to conform to public safety

regulations and controls..."

CONCLUSIONS AND IMPLICATIONS FOR RESEARCH

A review of the case law dealing with challenges to headgear legislation leads to the following

conclusions about these laws:

• With a single exception, every state court of last resort that considered the issue has upheld

headgear legislation as a valid exercise of state power.

• The courts are not in agreement, however, as to what is the public benefit justifying the

constitutionality of headgear legislation. Some have pointed to indirect social benefits such as

lowered welfare costs, stemming from helmet-use laws; other courts have chosen to stress

more direct benefits, principally the avoidance of multivehicle crashes caused by unhelmeted

cyclists who lose control of their cycles.

The almost unanimous conclusion of the courts, that states may constitutionally enact headgear

legislation, establishes the narrow legal principle that there exists no constitutional prohibition against passing and enforcing helmet-use statutes. The judicial opinions do not necessarily establish whether it is wise or politically advantageous to enact such legislation.

No reported cases involving challenges to headgear legislation have been decided since 1977.

After Congress overrode the DOT helmet standard, opponents of headgear legislation took their case to the state legislatures. Within two years of the congressional action, a majority of states repealed or weakened their helmet-use statutes; however, the trend toward repeal has since slowed.

Nevertheless, legislative interest in headgear statutes remains high, as efforts to strengthen or weaken them are being considered in more than half the states. Debate at the state level has focused on the cyclist's liberty and privacy on one hand, and the resulting losses on the other. For that reason, the constitutional arguments formerly considered by the courts remain important social and political issues that proponents of helmet-use laws and other safety legislation will continue to face. Future research should continue to focus on legislative action concerning headgear statutes, as well as the reasons why legislators choose to retain, weaken, or strengthen them.

=======

REGARDING THE SALE OF HELMETS:

Following is the official U.S. regulation, or "law" for what we motorcyclists in the U.S. know as the DOT regulations covering motorcycle helmets. In other words, a motorcycle helmet manufacturer would have to submit a helmet model to testing to the following regulations to meet DOT standards and the right to place the DOT sticker on the back of the helmet.

The Federal Motor Vehicle Safety Standard (FMVSS) known as FMVSS 218 (49CFR571.218), describes in great detail the requirements for "DOT" certification of all helmets sold in the United States for use by motorcyclists. Helmets that do not meet the minimal DOT certification standards may not be sold as "motorcycle helmets."

The Snell Memorial Foundation is an additional certification source intended to provide testing standards and "Snell" certification to a different standard than FMVSS 218. The Snell standards don't replace the DOT standards; meeting Snell standards is completely voluntary. All motorcycle helmets sold in the U.S.A. must be DOT "certified", in that they must have gone through the proper procedures in a certified testing lab to meet DOT standards for motorcycle helmets, but they are not required to be Snell certified.

A motorcycle helmet that carries both DOT and Snell standards may have gone through different testing schemes, but may not necessarily be superior to helmets that meets the DOT standard. There is some controversy over standards and testing, and it gets even more complicated if you consider the European ECE 22.05 standard.

See also the new SHARP motorcycle helmet rating system used in the UK.

Code of Federal Regulations

Title 49, Volume 5 - Revised as of October 1, 2001

CITE: 49CFR571.218

[Page 643-659]

TITLE 49--TRANSPORTATION

CHAPTER V--NATIONAL HIGHWAY TRAFFIC SAFETY ADMINISTRATION, DEPARTMENT OF TRANSPORTATION

PART 571--FEDERAL MOTOR VEHICLE SAFETY STANDARDS--Table of Contents

Subpart B--Federal Motor Vehicle Safety Standards

Sec. 571.218 Standard No. 218; Motorcycle helmets.

S1. Scope. This standard establishes minimum performance requirements for helmets designed for use by motorcyclists and other motor vehicle users.

S2. Purpose. The purpose of this standard is to reduce deaths and injuries to motorcyclists and other motor vehicle users resulting from head impacts.

S3. Application. This standard applies to all helmets designed for use by motorcyclists and other motor vehicle users.

S4. Definitions.

Basic plane means a plane through the centers of the right and left external ear openings and the lower edge of the eye sockets (Figure 1) of a reference headform (Figure 2) or test headform.

Helmet positioning index means the distance in inches, as specified by the manufacturer, from the lowest point of the brow opening at the lateral midpoint of the helmet to the basic plane of a reference headform, when the helmet is firmly and properly positioned on the reference headform.

Midsagittal plane means a longitudinal plane through the apex of a reference headform or test headform that is perpendicular to the basic plane (Figure 3).

Reference headform means a measuring device contoured to the dimensions of one of the three headforms described in Table 2 and Figures 5 through 8 with surface markings indicating the locations of the basic, mid-sagittal, and reference planes, and the centers of the external ear openings.

Reference plane means a plane above and parallel to the basic plane on a reference headform or test headform (Figure 2) at the distance indicated in Table 2.

Retention system means the complete assembly by which the helmet is retained in position on the head during use.

Test headform means a test device contoured to the dimensions of one of the three headforms described in Table 2 and Figures 5 through 8 with surface markings indicating the locations of the basic, mid-sagittal, and reference planes.

S5. Requirements. Each helmet shall meet the requirements of S5.1, S5.2, and S5.3 when subjected to any conditioning procedure specified in S6.4, and tested in accordance with S7.1, S7.2, and S7.3.

S5.1 Impact attenuation. When an impact attenuation test is conducted in accordance with S7.1, all of the following requirements shall be met: (a) Peak accelerations shall not exceed 400g; (b) Accelerations in excess of 200g shall not exceed a cumulative duration of 2.0 milliseconds; and (c) Accelerations in excess of 150g shall not exceed a cumulative duration of 4.0 milliseconds. S5.2 Penetration. When a penetration test is conducted in accordance with S7.2, the striker shall not contact the surface of the test headform.

S5.3 Retention system.

S5.3.1 When tested in accordance with S7.3: (a) The retention system or its components shall attain the loads specified without separation; and (b) The adjustable portion of the retention system test device shall not move more than 1 inch (2.5 cm) measured between preliminary and test load positions.

S5.3.2 Where the retention system consists of components which can be independently fastened without securing the complete assembly, each such component shall independently meet the requirements of S5.3.1.

S5.4 Configuration. Each helmet shall have a protective surface of continuous contour at all points on or above the test line described in S6.2.3. The helmet shall provide peripheral vision clearance of at least 105 deg. to each side of the mid-sagittal plane, when the helmet is adjusted as specified in S6.3. The vertex of these angles, shown in Figure 3, shall be at the point on the anterior surface of the reference headform at the intersection of the mid-sagittal and basic planes. The brow opening of the helmet shall be at least 1 inch (2.5 cm) above all points in the basic plane that are within the angles of peripheral vision (see Figure 3).

S5.5 Projections. A helmet shall not have any rigid projections inside its shell. Rigid projections outside any helmet's shell shall be limited to those required for operation of essential accessories, and shall not protrude more than 0.20 inch (5 mm).

S5.6 Labeling.

S5.6.1 Each helmet shall be labeled permanently and legibly, in a manner such that the label(s) can be read easily without removing padding or any other permanent part, with the following:

(a) Manufacturer's name or identification.

(b) Precise model designation.

(c) Size.

(d) Month and year of manufacture. This may be spelled out (for example, June 1988), or expressed in numerals (for example, 6/88).

(e) The symbol DOT, constituting the manufacturer's certification that the helmet conforms to the applicable Federal motor vehicle safety standards. This symbol shall appear on the outer surface, in a color that contrasts with the background, in letters at least \3/8\ inch (1 cm) high, centered laterally with the horizontal centerline of the symbol located a minimum of 1\1/8\ inches (2.9 cm) and a maximum of 1\3/ 8\ inches (3.5 cm) from the bottom edge of the posterior portion of the helmet.

(f) Instructions to the purchaser as follows:

(1) ``Shell and liner constructed of (identify type(s) of materials).

(2) ``Helmet can be seriously damaged by some common substances without damage being visible to the user. Apply only the following: (Recommended cleaning agents, paints, adhesives, etc., as appropriate).

(3) ``Make no modifications. Fasten helmet securely. If helmet experiences a severe blow, return it to the manufacturer for inspection, or destroy it and replace it.''

(4) Any additional relevant safety information should be applied at the time of purchase by means of an attached tag, brochure, or other suitable means.

S5.7 Helmet positioning index. Each manufacturer of helmets shall establish a positioning index for each helmet he manufactures. This index shall be furnished immediately to any person who requests the information, with respect to a helmet identified by manufacturer, model designation, and size.

S6. Preliminary test procedures. Before subjecting a helmet to the testing sequence specified in S7., prepare it according to the procedures in S6.1, S6.2, and S6.3.

S6.1 Selection of appropriate headform.

S6.1.1 A helmet with a manufacturer's designated discrete size or size range which does not exceed 6\3/4\ (European size: 54) is tested on the small headform. A helmet with a manufacturer's designated discrete size or size range which exceeds 6\3/4\, but does not exceed 7\1/2\ (European size: 60) is tested on the medium headform. A helmet with a manufacturer's designated discrete size or size range which exceeds 7\1/ 2\ is tested on the large headform.

S6.1.2 A helmet with a manufacturer's designated size range which includes sizes falling into two or all three size ranges described in S6.1.1 is tested on each headform specified for each size range. S6.2 Reference marking.

S6.2.1 Use a reference headform that is firmly seated with the basic and reference planes horizontal. Place the complete helmet to be tested on the appropriate reference headform, as specified in S6.1.1 and S6.1.2.

S6.2.2 Apply a 10-pound (4.5 kg) static vertical load through the helmet's apex. Center the helmet laterally and seat it firmly on the reference headform according to its helmet positioning index.

S6.2.3 Maintaining the load and position described in S6.2.2, draw a line (hereinafter referred to as ``test line'') on the outer surface of the helmet coinciding with portions of the intersection of that service with the following planes, as shown in Figure 2: (a) A plane 1 inch (2.5 cm) above and parallel to the reference plane in the anterior portion of the reference headform; (b) A vertical transverse plane 2.5 inches (6.4 cm) behind the point on the anterior surface of the reference headform at the intersection of the mid-sagittal and reference planes; (c) The reference plane of the reference headform; (d) A vertical transverse plane 2.5 inches (6.4. cm) behind the center of the external ear opening in a side view; and (e) A plane 1 inch (2.5 cm) below and parallel to the reference plane in the posterior portion of the reference headform.

S6.3 Helmet positioning.

S6.3.1 Before each test, fix the helmet on a test headform in the position that conforms to its helmet positioning index. Secure the helmet so that it does not shift position before impact or before application of force during testing.

S6.3.2 In testing as specified in S7.1 and S7.2, place the retention system in a position such that it does not interfere with free fall, impact or penetration.

S6.4 Conditioning.

S6.4.1 Immediately before conducting the testing sequence specified in S7, condition each test helmet in accordance with any one of the following procedures: (a) Ambient conditions. Expose to a temperature of 70 deg.F(21 deg.C) and a relative humidity of 50 percent for 12 hours. (b) Low temperature. Expose to a temperature of 14 deg.F(-10 deg.C) for 12 hours. (c) High temperature. Expose to a temperature of 122 deg.F(50 deg.C) for 12 hours. (d) Water immersion. Immerse in water at a temperature of 77 deg.F(25 deg.C) for 12 hours.

S6.4.2 If during testing, as specified in S7.1.3 and S7.2.3, a helmet is returned to the conditioning environment before the time out of that environment exceeds 4 minutes, the helmet is kept in the environment for a minimum of 3 minutes before resumption of testing with that helmet. If the time out of the environment exceeds 4 minutes, the helmet is returned to the environment for a minimum of 3 minutes for each minute or portion of a minute that the helmet remained out of the environment in excess of 4 minutes or for a maximum of 12 hours, whichever is less, before the resumption of testing with that helmet.

S7. Test conditions.

S7.1 Impact attenuation test.

S7.1.1 Impact attenuation is measured by determining acceleration imparted to an instrumented test headform on which a complete helmet is mounted as specified in S6.3, when it is dropped in guided free fall upon a fixed hemispherical anvil and a fixed flat steel anvil.

S7.1.2 Each helmet is impacted at four sites with two successive identical impacts at each site. Two of these sites are impacted upon a flat steel anvil and two upon a hemispherical steel anvil as specified in S7.1.10 and S7.1.11. The impact sites are at any point on the area above the test line described in paragraph S6.2.3, and separated by a distance not less than one-sixth of the maximum circumference of the helmet in the test area.

S7.1.3 Impact testing at each of the four sites, as specified in S7.1.2, shall start at two minutes, and be completed by four minutes, after removal of the helmet from the conditioning environment.

S7.1.4 (a) The guided free fall drop height for the helmet and test headform combination onto the hemispherical anvil shall be such that the minimum impact speed is 17.1 feet/second (5.2 m/sec). The minimum drop height is 54.5 inches (138.4 cm). The drop height is adjusted upward from the minimum to the extent necessary to compensate for friction losses. (b) The guided free fall drop height for the helmet and test headform combination onto the flat anvil shall be such that the minimum impact speed is 19.7 ft./sec (6.0 m/sec). The minimum drop height is 72 inches (182.9 cm). The drop height is adjusted upward from the minimum to the extent necessary to compensate for friction losses.

S7.1.5 Test headforms for impact attenuation testing are constructed of magnesium alloy (K-1A), and exhibit no resonant frequencies below 2,000 Hz.

S7.1.6 The monorail drop test system is used for impact attenuation testing.

S7.1.7 The weight of the drop assembly, as specified in Table 1, is the combined weight of the test headform and the supporting assembly for the drop test. The weight of the supporting assembly is not less than 2.0 lbs. and not more than 2.4 lbs. (0.9 to 1.1 kg). The supporting assembly weight for the monorail system is the drop assembly weight minus the combined weight of the test headform, the headform's clamp down ring, and its tie down screws.

S7.1.8 The center of gravity of the test headform is located at the center of the mounting ball on the supporting assembly and lies within a cone with its axis vertical and forming a 10 deg. included angle with the vertex at the point of impact. The center of gravity of the drop assembly lies within the rectangular volume bounded by x = -0.25 inch (-0.64 cm), x = 0.85 inch (2.16 cm), y = 0.25 inch (0.64 cm), and y = -0.25 inch (-0.64 cm) with the origin located at the center of gravity of the test headform.

The rectangular volume has no boundary along the z-axis. The x-y-z axes are mutually perpendicular and have positive or negative designations in accordance with the right-hand rule (See Figure 5). The origin of the coordinate axes also is located at the center of the mounting ball on the supporting assembly (See Figures 6, 7, and 8). The x-y-z axes of the test headform assembly on a monorail drop test equipment are oriented as follows: From the origin, the x-axis is horizontal with its positive direction going toward and passing through the vertical centerline of the monorail. The positive z-axis is downward. The y-axis also is horizontal and its direction can be decided by the z- and x-axes, using the right-hand rule.

S7.1.9 The acceleration transducer is mounted at the center of gravity of the test headform with the sensitive axis aligned to within 5 deg. of vertical when the test headform assembly is in the impact position. The acceleration data channel complies with SAE Recommended Practice J211 JUN 80, Instrumentation for Impact Tests, requirements for channel class 1,000.

S7.1.10 The flat anvil is constructed of steel with a 5-inch (12.7 cm) minimum diameter impact face, and the hemispherical anvil is constructed of steel with a 1.9 inch (4.8 cm) radius impact face.

S7.1.11 The rigid mount for both of the anvils consists of a solid mass of at least 300 pounds (136.1 kg), the outer surface of which consists of a steel plate with minimum thickness of 1 inch (2.5 cm) and minimum surface area of 1 ft.2 (929 cm2 ).

S7.1.12 The drop system restricts side movement during the impact attenuation test so that the sum of the areas bounded by the acceleration-time response curves for both the x- and y-axes (horizontal axes) is less than five percent of the area bounded by the acceleration- time response curve for the vertical axis.

S7.2 Penetration test.

S7.2.1 The penetration test is conducted by dropping the penetration test striker in guided free fall, with its axis aligned vertically, onto the outer surface of the complete helmet, when mounted as specified in S6.3, at any point above the test line, described in S6.2.3, except on a fastener or other rigid projection.

S7.2.2 Two penetration blows are applied at least 3 inches (7.6 cm) apart, and at least 3 inches (7.6 cm) from the centers of any impacts applied during the impact attenuation test. S7.2.3 The application of the two penetration blows, specified in S7.2.2, starts at two minutes and is completed by four minutes, after removal of the helmet from the conditioning environment.

S7.2.4 The height of the guided free fall is 118.1 inches (3 m), as measured from the striker point to the impact point on the outer surface of the test helmet.

S7.2.5 The contactable surface of the penetration test headform is constructed of a metal or metallic alloy having a Brinell hardness number no greater than 55, which will permit ready detection should contact by the striker occur. The surface is refinished if necessary before each penetration test blow to permit detection of contact by the striker.

S7.2.6 The weight of the penetration striker is 6 pounds, 10 ounces (3 kg).

S7.2.7 The point of the striker has an included angle of 60 deg., a cone height of 1.5 inches (3.8 cm), a tip radius of 0.02 inch (standard 0.5 millimeter radius) and a minimum hardness of 60 Rockwell, C-scale.

S7.2.8 The rigid mount for the penetration test headform is as described in S7.1.11.

S7.3 Retention system test.

S7.3.1 The retention system test is conducted by applying a static tensile load to the retention assembly of a complete helmet, which is mounted, as described in S6.3, on a stationary test headform as shown in Figure 4, and by measuring the movement of the adjustable portion of the retention system test device under tension.

S7.3.2 The retention system test device consists of both an adjustable loading mechanism by which a static tensile load is applied to the helmet retention assembly and a means for holding the test headform and helmet stationary. The retention assembly is fastened around two freely moving rollers, both of which have a 0.5 inch (1.3 cm) diameter and a 3-inch (7.6 cm) center-to-center separation, and which are mounted on the adjustable portion of the tensile loading device (Figure 4). The helmet is fixed on the test headform as necessary to ensure that it does not move during the application of the test loads to the retention assembly.

S7.3.3 A 50-pound (22.7 kg) preliminary test load is applied to the retention assembly, normal to the basic plane of the test headform and symmetrical with respect to the center of the retention assembly for 30 seconds, and the maximum distance from the extremity of the adjustable portion of the retention system test device to the apex of the helmet is measured.

S7.3.4 An additional 250-pound (113.4 kg) test load is applied to the retention assembly, in the same manner and at the same location as described in S7.3.3, for 120 seconds, and the maximum distance from the extremity of the adjustable portion of the retention system test device to the apex of the helmet is measured.

Appendix to Sec. 571.218

(wBW Note: Graphics have been omitted.)

Table 1--Weights for Impact Attenuation Test Drop Assembly; Test headform size Weight \1\--1b(kg); Small - 7.8 (3.5 kg).; Medium - 11.0 (5.0 kg).; Large - 13.4 (6.1 kg). \1\ Combined weight of instrumented test headform and supporting assembly for drop test.

skip to main |

skip to sidebar

Bill & Annie

Art Hall & Rusty

NUFF SAID.......

OOHRAH

ONCE A MARINE,ALWAYS A MARINE

GIVING BACK

MOUNT SOLEDAD

BIKINI BIKE WASH AT SWEETWATER

FRIENDS

BILL,WILLIE G, PHILIP

GOOD FRIENDS

hanging out

brothers

GOOD FRIENDS

Good Friends

Hanging Out

Bill & Annie

Art Hall & Rusty

Art Hall & Rusty

NUFF SAID.......

NUFF SAID......

Mount Soledad

BALBOA NAVAL HOSPITAL

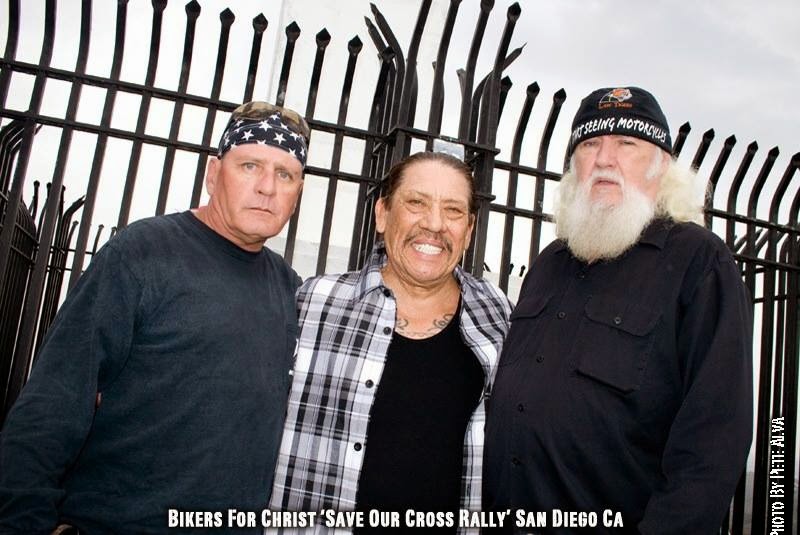

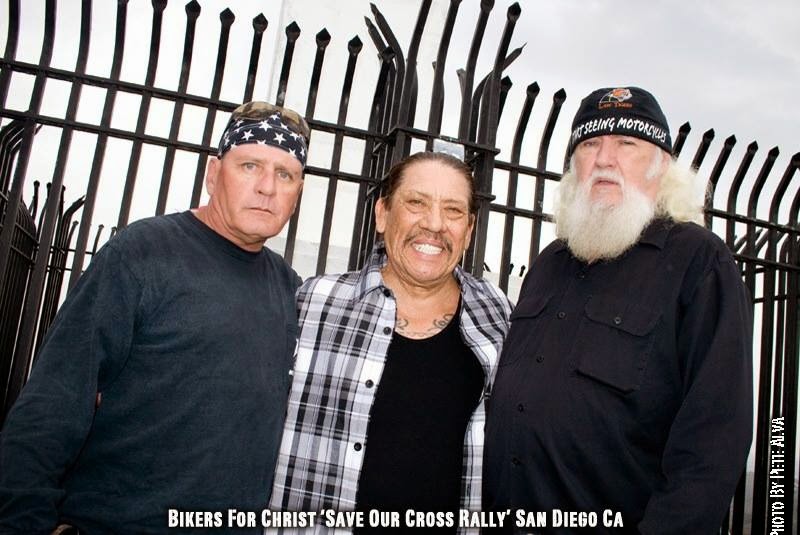

RUSTY DANNY

ANNIE KO PHILIP

PHILIP & ANNIE

OUT & ABOUT

OOHRAH...

OOHRAH

ONCE A MARINE,ALWAYS A MARINE

ONCE A MARINE,ALWAYS A MARINE

American Soldier Network GIVING BACK

GIVING BACK

CATHY & BILL

PHILIP & DANNY & BILL

MOUNT SOLEDAD

bills today

EMILIO & PHILIP

WATER & POWER

WATER & POWER

bootride2013

BIKINI BIKE WASH AT SWEETWATER

ILLUSION OPEN HOUSE

FRIENDS

GOOD FRIENDS

BILL,WILLIE G, PHILIP

GOOD FRIENDS

GOOD FRIENDS

Friends

- http://www.ehlinelaw.com/losangeles-motorcycleaccidentattorneys/

- Scotty westcoast-tbars.com

- Ashby C. Sorensen

- americansoldiernetwork.org

- blogtalkradio.com/hermis-live

- davidlabrava.com

- emiliorivera.com/

- http://kandymankustompaint.com

- http://pipelinept.com/

- http://womenmotorcyclist.com

- http://www.ehlinelaw.com

- https://ammo.com/

- SAN DIEGO CUSTOMS

- www.biggshd.com

- www.bighousecrew.net

- www.bikersinformationguide.com

- www.boltofca.org

- www.boltusa.org

- www.espinozasleather.com

- www.illusionmotorcycles.com

- www.kennedyscollateral.com

- www.kennedyscustomcycles.com

- www.listerinsurance.com

- www.sweetwaterharley.com

Hanging out

hanging out

Good Friends

brothers

GOOD FRIENDS

EMILIO & SCREWDRIVER

GOOD FRIENDS

Danny Trejo & Screwdriver

Good Friends

Navigation

Welcome to Bikers of America, Know Your Rights!

“THE BIKERS OF AMERICA, THE PHIL and BILL SHOW”,

A HARDCORE BIKER RIGHTS SHOW THAT HITS LIKE A BORED AND STROKED BIG TWIN!

ON LIVE TUESDAY'S & THURDAY'S AT 6 PM P.S.T.

9 PM E.S.T.

CATCH LIVE AND ARCHIVED SHOWS

FREE OF CHARGE AT...

BlogTalkRadio.com/BikersOfAmerica.

Two ways to listen on Tuesday & Thursday

1. Call in number - (347) 826-7753 ...

Listen live right from your phone!

2. Stream us live on your computer: http://www.blogtalkradio.com/bikersofamerica.

A HARDCORE BIKER RIGHTS SHOW THAT HITS LIKE A BORED AND STROKED BIG TWIN!

ON LIVE TUESDAY'S & THURDAY'S AT 6 PM P.S.T.

9 PM E.S.T.

CATCH LIVE AND ARCHIVED SHOWS

FREE OF CHARGE AT...

BlogTalkRadio.com/BikersOfAmerica.

Two ways to listen on Tuesday & Thursday

1. Call in number - (347) 826-7753 ...

Listen live right from your phone!

2. Stream us live on your computer: http://www.blogtalkradio.com/bikersofamerica.

Good Times

Hanging Out

Key Words

- about (3)

- contact (1)

- TENNESSEE AND THUNDER ON THE MOUNTAIN (1)

- thinking (1)

- upcoming shows (2)

Blog Archive

-

▼

2010

(4242)

-

▼

November

(629)

- NATIONWIDE, Americans Are Living (And Dying) In A ...

- CYBER SCAMS, BE WARNED....The 12 cyber scams of Ch...

- Media Campaign Begins, Head Injuries: Why Motorcyc...

- Football Helmets - NY Times, Used helmets worn by ...

- New Zealand, Warehouse new gang base

- Growth of San Diego's Navy fleet tied to tension i...

- Canada, ,Salmon Arm, Kelowna. 'They were up to no...

- SPINELESS PUKE BAG DISTRICT ATTORNEY, JONATHAN BLO...

- What are some good responses to this helmet statem...

- DOT vs. ECE Helmet Safety Standards

- Australia, Sydney, Strike force digs deep into dea...

- South Africa, Car driver causes chaos at PE bikers...

- Washington, DC, EDITORIAL: TSA's security charade

- New Delhi,India, IAS Officer Arrested For Barterin...

- Denver, CO. Donors line up to replace lost Christm...

- THE LAW AND YOU 1

- USA, The Eternal Value of Privacy, "Absolute power...

- Australia, Bandidos member found with gun......

- F .B. I.Deprivation of Rights Under Color Of LAW

- How to obtain a CCW permit, San Diego,Ca

- New Zealand, Marlborough, Lone Legion M/C, Warehou...

- CCW (Concealed- Weapons Permit) San Diego, Ca, Lit...

- US v. Camp Zoe

- DAYTONA, Private Company’s Registration of Bike We...

- CHESTER, S.C. These bikers ride for a cause, Iron ...

- Nevada, Carson City Probation Officer Accused of S...

- DUBAI, United Arab Emirates, Swiss motorbike cham...

- CAN WE RECORD COPS? Phone Calls and Research by Jo...

- Well, if you’re not doing anything wrong and have ...

- ANGOLA 3, IN ROBERT KING’S WORDS: “EVERYTHING LEGA...

- Ex-Marine Marching Across America Stops in Trenton

- South Attleboro, MA. Joes Sock Fund – Can you help?

- Midland, Texas - Feds Push for Nationwide Motorcyc...

- DOJ Components' FOIA Service Centers/Liaisons

- United States Dept of Justice, Freedom of Informat...

- READERS SOUND OFF, Case Against Motorcycle Helmet ...

- Bahrain, Parading patriotism!!!!!!!!!!!!!!!!

- Appeals court derails use of GPS in case, Decides ...

- LITTLETON, Colo. Charity donations stolen

- Sons of Anarchy: Sonny Barger Cameo, Featuring Att...

- Freedom of Information Act ,FOIA Reference Mater...

- More excellent info here for helmets Transportatio...

- New Zealand, Gang members grieve for powerful, fe...

- CAN WE RECORD COPS?

- North Park, San Diego,Ca, Pepper-Spraying Men Rob ...

- OCEANSIDE, Calif. FYI: Marine Corps presents most ...

- EXCLUSIVE: Hells Angel Sonny Barger to Guest on 'S...

- United States Marine Corps, Marines Move Heavy Met...

- Canada, Hells Angels busted in Salmon Arm

- CCW (Concealed- Weapons Permit) San Diego

- Phoenix, AZ, Police ID Man Shot to Death Near Priv...

- Health care dictatorship: A crime against America

- Florida, Bikers, City Hall team up to honor veterans

- Fully Informed Jury Association

- Canada, Kelowna connection to bikers bust, Police...

- Company says it owns Bike Week name

- Where The Burgess Case Stands Now

- Photo`s, Videos,or Recording Your Traffic Stop, of...

- Australia, Senior officer 'hacked police computer ...

- Mexico's modern city succumbs to drug violence, MO...

- The One Big Investigation

- San Diego drug tunnel had railcar, tons of pot, an...

- Canada, Police 'harassment' frustrates Pammett

- Australia, Bikies charged over fight in Fremantle

- Australia– Wiley Park, Alleged Bandidos OMCG memb...

- New York City Police Photograph Irises of Suspects

- FBI Thwarts Somali-Born Teen's Car Bombing, SCORE ...

- Orange County, CA, He Shall Be Set Free

- The First Banning of an MCs Colors in the USA

- Oppose S.510 - Do not take the chance of regulatin...

- San Diego,Ca, It’s easier riding for local motorcy...

- ALBANY, GA, Motorcycle club making holidays extra...

- Fond du Lac, WI - FdL police officer gets 3-day su...

- Taking Pictures of a Police Officer

- Biker Donations Help Feed Boys, Girls

- The Feds’ Illegal/Unauthorized/Murderous War on Bi...

- PENNSYLVANIA:Helmet debate begins anew NTSB puts i...

- Australia, Gypsy Jokers 'drug running' to mines

- Gangs Still Active in US Military

- Introducing Preacher Chuck D's Alpha Biker Road Rash

- 1st Annual Big Tom Berg Memorial Toy Drive

- New Zealand, Gang members grieve for powerful, fea...

- Australia, Bikers on drug charges in WA

- Australia, Bikie's partner guilty of stealing

- The Case Against Motorcycle Helmet Laws, Biker Ri...

- Sons of Silence Harley to Law Museum

- Australia, Bandidos gang member points loaded gun ...

- Australia, Finks front court over CCC contempt cha...

- Canada, Back-to-back suspicious fires in B.C. link...

- Former Pagan held for trial in shooting of College...

- Australia, Finks charged with contempt over motor...

- United Kingdom, Police chief faces misconduct probe

- QUOTES,

- Australia, Finks bikies face contempt charges in WA

- Co-Sponsor H.R. 1475 Good Time Bill

- Not specifically biker related... but certainly ri...

- SOUTH CAROLINA: NTSB Asks States to Improve Motorc...

- Pennsylvania, Helmetless riding a costly freedom

- Massachusetts, Attorney Paul Lancia Joins New Eng...

- "Hermis Live!"- 46 Minutes UNTIL SHOW

-

▼

November

(629)

Bikers of America, Know Your Rights!... Brought to you by Phil and Bill

Philip, a.k.a Screwdriver, is a proud member of Bikers of Lesser Tolerance, and the Left Coast Rep

of B.A.D (Bikers Against Discrimination) along with Bill is a biker rights activist and also a B.A.D Rep, as well, owner of Kennedy's Custom Cycles