OFF THE WIRE

http://www.webbikeworld.com/eicma-2010/nolan-helmets/dot-vs-ece-helmet-safety-standards.htm DOT vs. ECE Helmet Safety Standards.

Motorcycle Helmet Safety Standards

by Rick Korchak for webBikeWorld.com

[http://www.webbikeworld.com/includes/google/336x280-2010.htm]

Background

In Part 1 of this article, I described my detailed tour of the Nolan Helmets factory in Brembate di Sopra, Italy.

I learned about the polycarbonate motorcycle helmet manufacturing process and all of the work that it takes to create a Nolan helmet.

During my tour, I also visited a separate Nolan facility used for manufacturing the composite shells of the Nolan Group X-Lite helmets.

The process is completely different, although the painting and decal work is similar.

Nolan has developed many trade secrets for manufacturing their composite helmets and I was sworn to secrecy at the front gate, so unfortunately I'm not at liberty to discuss it.

However, I also visited the helmet safety standards test labs at Nolan, where both the polycarbonate and the composite X-Lite helmets are developed and tested and the designs certified to meet the various worldwide standards in the over 70 countries where Nolan helmets are sold.

I'd like to again thank the Nolan staff for providing this most excellent and enlightening tour and for allowing me such free access to the entire facility. And don't forget lunch!

Introduction

A huge amount of information -- or should I say misinformation -- exists regarding the differences between worldwide motorcycle helmet safety standards.

Unfortunately, even with all that information, there isn't a consensus among motorcycle riders on which standard provides the most protective, or "safest" helmet. Even the experts don't agree (and apparently don't really know) which test and what type of forces will optimize protection for the rider's head.

Another facet of this controversy is that many of the tests have apparently been developed without solid scientific evidence or backing for their efficacy, which has resulted in differences among the standards, such as the maximum G force over time that are called out. This is the source of some of the confusion; surely the criteriae and testing procedures among the standards would be similar if the data and evidence was available (and everyone agreed)?

Thus, the subject of motorcycle helmet safety standards is highly complex, so it's no wonder the general riding public is confused.

I wish I could say that I have learned enough to give you some concrete answers and facts on the differences. But although I've either owned or worn over 200 helmets in the last 10 years and am deeply immersed in the subject for a living, I'm still far from an expert on these matters. I pity the beginning rider that walks into the local shop to buy a first helmet.

Knowledge is power, so they say, but where there is power, there is danger. Too much or too little or misunderstandings are rife when it comes to helmet standards. So at the risk of adding even more confusion to the discussions, I'll convey some of the information gleaned during my visit to the Nolan labs and I will describe some of the rather surprising (at least to me) findings.

Notes and Disclaimers

This article is absolutely not designed to provide any type of definitive answers on this topic. I am far from an expert on this. It is simply one rider's observations on some of the differences and issues surrounding this complex subject.

Although I have labored to ensure that all of my facts and information are correct, it is possible that more clarification may be required, so contributions from readers who have expertise in the area of motorcycle helmet safety standards are welcomed and in fact, encouraged. It would be nice to develop a dialogue about this topic that could be shared with our readers.

OK, let's begin!

The Metalheads

Nolan has complete testing laboratory facilities that include drop rigs and all of the other technology needed to test helmets to all worldwide applicable safety standards. The facilities are also used for research and development on new designs, new materials and helmets for the Nolan, X-Lite and Grex lines of helmets that the Nolan Group produces.

Attached to the testing lab is Nolan's internal quality control facility, with all sorts of custom-made devices and machinery to "torture test" helmets, visor and face shield operation, sun shades and everything else that makes up a modern helmet. They even have an environmental test chamber to provide accelerated testing on moisture and humidity, temperature extremes and more.

The largest testing structures in the standards testing lab are the helmet drop test rigs. These are used to drop the helmets from a specified distance on to various metal devices, or "anvils", to measure the amount of energy absorbed by the helmet and liner.

In the drop test, a helmet is placed on a headform, which is a standardized metal form that is more or less in the shape of a human head. The design and weight of each headform is very specific and is called out in each standard.

The Headform

Which brings us to the first real difference in the DOT and ECE (and Australian) standards: the headforms are not the same shape. I might even say they're completely different, although there are specific technical reasons behind each design.

As you can see from the following photos (and in the video below), the DOT headform, on the right in the photos, looks wider and flatter. The ECE headform (on the left in the photo directly below) bears more of a resemblance to a human head shape, while the Australian headform is sort of a hybrid of the DOT and ECE shapes.

Headform Shapes, Rear View: DOT (left); Australian (Center); ECE (Right).

[http://www.webbikeworld.com/includes/google/468x60-2010.htm]

Headform Sizes and Shapes

The DOT headform comes in three different sizes: S, M and L (reference the 571.218 standard information in the next section). Size small weighs 7.8 lbs. (3.5 kg); size medium weighs 11.0 lbs.(5.0 kg); and size large weighs 13.4 lbs. (6.1 kg). This range is designed to cover the estimated range of human head weights, which is said to range from about 3.5 kg to 5.0 kg.

Surprisingly, there doesn't seem to be a consensus on exact head weights or head dimensions vs. head size (but we all know that some human heads are much lighter than others, right?). In any case, for purposes of motorcycle helmet protection, I'd guess that a few grams here or there isn't going to make much of a difference. But what about those shapes?

The ECE headform comes in 8 different head sizes, ranging from size 50 to 62 with a mass of 3.1 kg for the size 50 to 6.1 kg for the size 62 (reference the ECE Standard No. 22 in the next section).

To summarize the headform differences, DOT uses three headforms and ECE uses eight. Their weight ranges are about the same. In theory, the ECE headform weights, spread across a larger range of headform sizes, might allow the helmet manufacturer to calibrate the EPS (expanded polystyrene) liner for the particular helmet size.

So which headform more accurately represents your head? Like most of the other issues surrounding motorcycle helmet protection standards, there really isn't an answer. I know of no studies that have compared the relative protection capabilities of the headforms (although such studies may exist), so it's difficult to say whether one approach is more valid than the other.

Headform Shape vs. Helmet Fit?

One other noticeable difference is in the shape of the headforms. The DOT, ECE and other helmet standards go into great detail on the size, weight, shape and construction of the headforms. Each headform has a large matrix of dimensions that are used to program the computer-controlled machine tools that make the headforms. This ensures the accuracy of the standard headform size and weight.

Looking at the headforms, the ECE shape appears to be narrower than the DOT shape. The DOT headform runs from 4.784 in. for the size small to 5.350 in. for the size medium to 5.720 in. for size large, while the ECE headforms range from 88.1 mm (3.4685 in.) for the size A to 108.7 mm (4.2795 in.) for size O -- quite a difference.

Again, I'm not sure what inferences can be drawn from these differences other than perhaps the narrower range of sizes for the ECE headforms may be in some way responsible for the differences we experience in the internal shape of ECE-only helmets? If the helmet is optimized for a specific headform shape, then it's possible that shape will carry over into the fit that the rider experiences.

DOT headform specifications (size M).

Standards and More Standards...

Monitoring changes to worldwide standards can be difficult, but motorcycle helmet safety standards are relatively stable, which is both good and bad news.

For example, the U.S. Department of Transportation, Federal Motor Carrier Safety Administration, Part 571, which contains the 571.218: Standard No. 218; Motorcycle Helmets that is colloquially known as the "DOT helmet safety standard", was first published under section 103 of the National Traffic and Motor Vehicle Safety Act of 1966 (reference).

Standard No. 218 was amended several times since then, with the last revision having been published way back in 1988 -- April 15th, to be exact.

Much has changed in the world since then, with technology, traffic and vehicle differences and in motorcycling and motorcycle helmets, so I'll leave it up to you to decide the merits of using a safety standard that hasn't changed in 22 years. Although I suppose we can look at the bright side and imagine that the standard is so good that it doesn't need to be changed, right?

Nevertheless, comparing the DOT and ECE standards is difficult at best and much like comparing apples and oranges. Depending on how you interpret the information, there are good points and not-so-good points about both standards.

And don't forget that DOT and ECE aren't the only helmet safety standards in the world. There is the Australian/New Zealand AS/NZS 1698:2006 standard; the Japanese JIS T 8133:2000 standard; the UK SHARP testing regime (info), which may or may not be a "standard" per se and more standards from Indonesia, India, Brazil and others.

By the way, the standard commonly referred to as "ECE 22.05" should probably more accurately be called "Regulation No. 22" because over 2 hours of searching while researching this article came up empty on any search results for "ECE 22.05".

This is discussed on the webBikeWorld ECE 22.05 information page, but to repeat, here is the page with .pdf downloads of the European motorcycle helmet safety standards.

And here is the direct link for the .pdf file of Regulation No. 22 "Protective Helmets and their visors for drivers and passengers of motor cycles and mopeds", which actually doesn't use the phrase "ECE 22.05", so I wonder where the term came from?

skip to main |

skip to sidebar

Bill & Annie

Art Hall & Rusty

NUFF SAID.......

OOHRAH

ONCE A MARINE,ALWAYS A MARINE

GIVING BACK

MOUNT SOLEDAD

BIKINI BIKE WASH AT SWEETWATER

FRIENDS

BILL,WILLIE G, PHILIP

GOOD FRIENDS

hanging out

brothers

GOOD FRIENDS

Good Friends

Hanging Out

Bill & Annie

Art Hall & Rusty

Art Hall & Rusty

NUFF SAID.......

NUFF SAID......

Mount Soledad

BALBOA NAVAL HOSPITAL

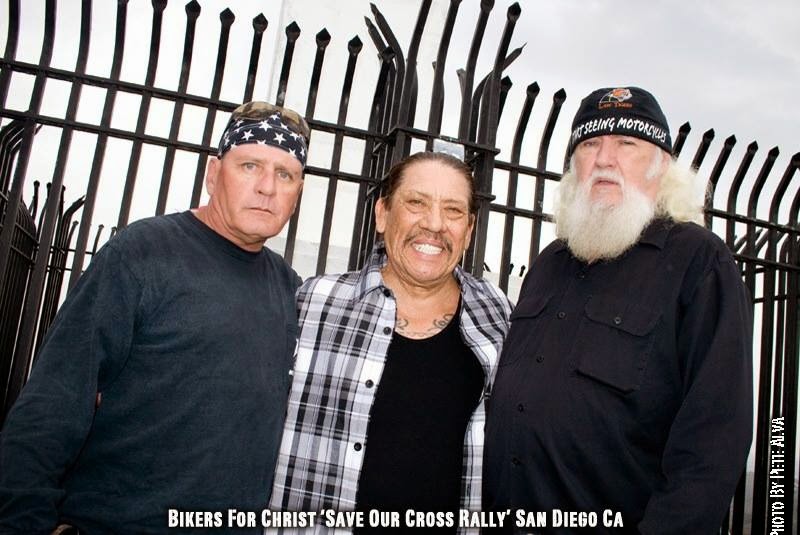

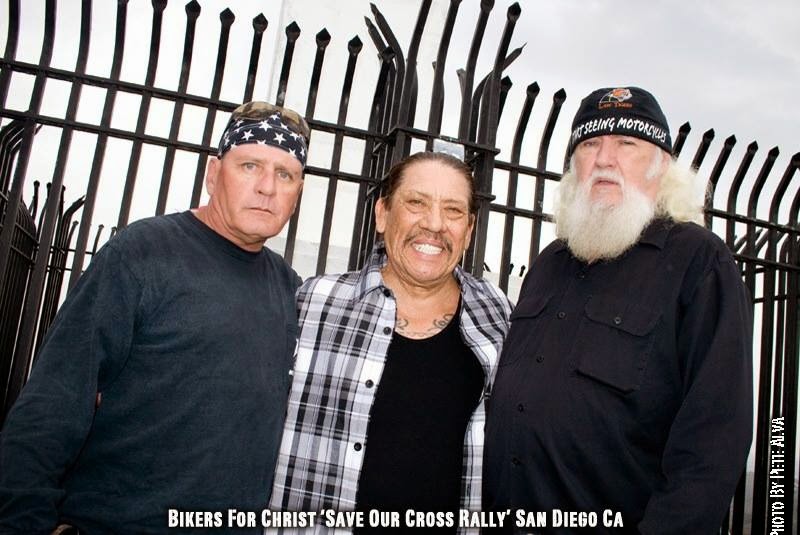

RUSTY DANNY

ANNIE KO PHILIP

PHILIP & ANNIE

OUT & ABOUT

OOHRAH...

OOHRAH

ONCE A MARINE,ALWAYS A MARINE

ONCE A MARINE,ALWAYS A MARINE

American Soldier Network GIVING BACK

GIVING BACK

CATHY & BILL

PHILIP & DANNY & BILL

MOUNT SOLEDAD

bills today

EMILIO & PHILIP

WATER & POWER

WATER & POWER

bootride2013

BIKINI BIKE WASH AT SWEETWATER

ILLUSION OPEN HOUSE

FRIENDS

GOOD FRIENDS

BILL,WILLIE G, PHILIP

GOOD FRIENDS

GOOD FRIENDS

Friends

- http://www.ehlinelaw.com/losangeles-motorcycleaccidentattorneys/

- Scotty westcoast-tbars.com

- Ashby C. Sorensen

- americansoldiernetwork.org

- blogtalkradio.com/hermis-live

- davidlabrava.com

- emiliorivera.com/

- http://kandymankustompaint.com

- http://pipelinept.com/

- http://womenmotorcyclist.com

- http://www.ehlinelaw.com

- https://ammo.com/

- SAN DIEGO CUSTOMS

- www.biggshd.com

- www.bighousecrew.net

- www.bikersinformationguide.com

- www.boltofca.org

- www.boltusa.org

- www.espinozasleather.com

- www.illusionmotorcycles.com

- www.kennedyscollateral.com

- www.kennedyscustomcycles.com

- www.listerinsurance.com

- www.sweetwaterharley.com

Hanging out

hanging out

Good Friends

brothers

GOOD FRIENDS

EMILIO & SCREWDRIVER

GOOD FRIENDS

Danny Trejo & Screwdriver

Good Friends

Navigation

Welcome to Bikers of America, Know Your Rights!

“THE BIKERS OF AMERICA, THE PHIL and BILL SHOW”,

A HARDCORE BIKER RIGHTS SHOW THAT HITS LIKE A BORED AND STROKED BIG TWIN!

ON LIVE TUESDAY'S & THURDAY'S AT 6 PM P.S.T.

9 PM E.S.T.

CATCH LIVE AND ARCHIVED SHOWS

FREE OF CHARGE AT...

BlogTalkRadio.com/BikersOfAmerica.

Two ways to listen on Tuesday & Thursday

1. Call in number - (347) 826-7753 ...

Listen live right from your phone!

2. Stream us live on your computer: http://www.blogtalkradio.com/bikersofamerica.

A HARDCORE BIKER RIGHTS SHOW THAT HITS LIKE A BORED AND STROKED BIG TWIN!

ON LIVE TUESDAY'S & THURDAY'S AT 6 PM P.S.T.

9 PM E.S.T.

CATCH LIVE AND ARCHIVED SHOWS

FREE OF CHARGE AT...

BlogTalkRadio.com/BikersOfAmerica.

Two ways to listen on Tuesday & Thursday

1. Call in number - (347) 826-7753 ...

Listen live right from your phone!

2. Stream us live on your computer: http://www.blogtalkradio.com/bikersofamerica.

Good Times

Hanging Out

Key Words

- about (3)

- contact (1)

- TENNESSEE AND THUNDER ON THE MOUNTAIN (1)

- thinking (1)

- upcoming shows (2)

Blog Archive

-

▼

2010

(4242)

-

▼

November

(629)

- NATIONWIDE, Americans Are Living (And Dying) In A ...

- CYBER SCAMS, BE WARNED....The 12 cyber scams of Ch...

- Media Campaign Begins, Head Injuries: Why Motorcyc...

- Football Helmets - NY Times, Used helmets worn by ...

- New Zealand, Warehouse new gang base

- Growth of San Diego's Navy fleet tied to tension i...

- Canada, ,Salmon Arm, Kelowna. 'They were up to no...

- SPINELESS PUKE BAG DISTRICT ATTORNEY, JONATHAN BLO...

- What are some good responses to this helmet statem...

- DOT vs. ECE Helmet Safety Standards

- Australia, Sydney, Strike force digs deep into dea...

- South Africa, Car driver causes chaos at PE bikers...

- Washington, DC, EDITORIAL: TSA's security charade

- New Delhi,India, IAS Officer Arrested For Barterin...

- Denver, CO. Donors line up to replace lost Christm...

- THE LAW AND YOU 1

- USA, The Eternal Value of Privacy, "Absolute power...

- Australia, Bandidos member found with gun......

- F .B. I.Deprivation of Rights Under Color Of LAW

- How to obtain a CCW permit, San Diego,Ca

- New Zealand, Marlborough, Lone Legion M/C, Warehou...

- CCW (Concealed- Weapons Permit) San Diego, Ca, Lit...

- US v. Camp Zoe

- DAYTONA, Private Company’s Registration of Bike We...

- CHESTER, S.C. These bikers ride for a cause, Iron ...

- Nevada, Carson City Probation Officer Accused of S...

- DUBAI, United Arab Emirates, Swiss motorbike cham...

- CAN WE RECORD COPS? Phone Calls and Research by Jo...

- Well, if you’re not doing anything wrong and have ...

- ANGOLA 3, IN ROBERT KING’S WORDS: “EVERYTHING LEGA...

- Ex-Marine Marching Across America Stops in Trenton

- South Attleboro, MA. Joes Sock Fund – Can you help?

- Midland, Texas - Feds Push for Nationwide Motorcyc...

- DOJ Components' FOIA Service Centers/Liaisons

- United States Dept of Justice, Freedom of Informat...

- READERS SOUND OFF, Case Against Motorcycle Helmet ...

- Bahrain, Parading patriotism!!!!!!!!!!!!!!!!

- Appeals court derails use of GPS in case, Decides ...

- LITTLETON, Colo. Charity donations stolen

- Sons of Anarchy: Sonny Barger Cameo, Featuring Att...

- Freedom of Information Act ,FOIA Reference Mater...

- More excellent info here for helmets Transportatio...

- New Zealand, Gang members grieve for powerful, fe...

- CAN WE RECORD COPS?

- North Park, San Diego,Ca, Pepper-Spraying Men Rob ...

- OCEANSIDE, Calif. FYI: Marine Corps presents most ...

- EXCLUSIVE: Hells Angel Sonny Barger to Guest on 'S...

- United States Marine Corps, Marines Move Heavy Met...

- Canada, Hells Angels busted in Salmon Arm

- CCW (Concealed- Weapons Permit) San Diego

- Phoenix, AZ, Police ID Man Shot to Death Near Priv...

- Health care dictatorship: A crime against America

- Florida, Bikers, City Hall team up to honor veterans

- Fully Informed Jury Association

- Canada, Kelowna connection to bikers bust, Police...

- Company says it owns Bike Week name

- Where The Burgess Case Stands Now

- Photo`s, Videos,or Recording Your Traffic Stop, of...

- Australia, Senior officer 'hacked police computer ...

- Mexico's modern city succumbs to drug violence, MO...

- The One Big Investigation

- San Diego drug tunnel had railcar, tons of pot, an...

- Canada, Police 'harassment' frustrates Pammett

- Australia, Bikies charged over fight in Fremantle

- Australia– Wiley Park, Alleged Bandidos OMCG memb...

- New York City Police Photograph Irises of Suspects

- FBI Thwarts Somali-Born Teen's Car Bombing, SCORE ...

- Orange County, CA, He Shall Be Set Free

- The First Banning of an MCs Colors in the USA

- Oppose S.510 - Do not take the chance of regulatin...

- San Diego,Ca, It’s easier riding for local motorcy...

- ALBANY, GA, Motorcycle club making holidays extra...

- Fond du Lac, WI - FdL police officer gets 3-day su...

- Taking Pictures of a Police Officer

- Biker Donations Help Feed Boys, Girls

- The Feds’ Illegal/Unauthorized/Murderous War on Bi...

- PENNSYLVANIA:Helmet debate begins anew NTSB puts i...

- Australia, Gypsy Jokers 'drug running' to mines

- Gangs Still Active in US Military

- Introducing Preacher Chuck D's Alpha Biker Road Rash

- 1st Annual Big Tom Berg Memorial Toy Drive

- New Zealand, Gang members grieve for powerful, fea...

- Australia, Bikers on drug charges in WA

- Australia, Bikie's partner guilty of stealing

- The Case Against Motorcycle Helmet Laws, Biker Ri...

- Sons of Silence Harley to Law Museum

- Australia, Bandidos gang member points loaded gun ...

- Australia, Finks front court over CCC contempt cha...

- Canada, Back-to-back suspicious fires in B.C. link...

- Former Pagan held for trial in shooting of College...

- Australia, Finks charged with contempt over motor...

- United Kingdom, Police chief faces misconduct probe

- QUOTES,

- Australia, Finks bikies face contempt charges in WA

- Co-Sponsor H.R. 1475 Good Time Bill

- Not specifically biker related... but certainly ri...

- SOUTH CAROLINA: NTSB Asks States to Improve Motorc...

- Pennsylvania, Helmetless riding a costly freedom

- Massachusetts, Attorney Paul Lancia Joins New Eng...

- "Hermis Live!"- 46 Minutes UNTIL SHOW

-

▼

November

(629)

Bikers of America, Know Your Rights!... Brought to you by Phil and Bill

Philip, a.k.a Screwdriver, is a proud member of Bikers of Lesser Tolerance, and the Left Coast Rep

of B.A.D (Bikers Against Discrimination) along with Bill is a biker rights activist and also a B.A.D Rep, as well, owner of Kennedy's Custom Cycles