OFF THE WIRE

agingrebel.com

Over the weekend The Wall Street Journal used Harley-Davidson as an example of America’s new, “lean” model of manufacturing. The term “lean” means what you probably already think it means. Lean means fewer hourly workers, reduced job security, more robots, higher profits and bigger bonuses for executives. Lean does not mean better or cheaper motorcycles.

This manufacturing model is sometimes called just-in-time manufacturing. It is largely the creation of an American statistician named W. Edwards Deming who went to Japan after the Second World War and helped reinvent Japanese manufacturing. Sometimes lean manufacturing is called “The Toyota Model.”

Keith Wandell

Harley is now leaner because of Chief Executive Keith Wandell. One of Wandell’s first decisions was that the York Assembly Plant, opened in 1973, was “obsolete.” At the time, the York plant employed about 2,400 workers who each made about $23 an hour, or about $45,000 a year. Wandell threatened to fire all those workers, close the plant and build a new one in Shelbyville, Kentucky. The workers’ union, the International Association of Machinists and Aerospace Workers, had virtually no leverage in the negotiations. The union could save some York jobs or lose them all. So, union members voted to save what they could.

The plant now has five job classifications instead of 62. The breadth of collective bargaining has been reduced. The old contract was 136 pages long. The current contract is less than half that. The York plant now employs about 1,000 hourly workers and a tenth of them are “casual” employees without job security. Robots and modern presses now do much of the work that used to be done by human beings.

Last year Wandell made $7,232,147.g

Bang Transformation

Ed Magee, the York Plant Manager told the Journal “This is a big bang transformation.”

A key idea in Harley’s new, lean relationship with its workers is to make the company better prepared to survive the next wave of economic recession expected in 2013. Harley sold about 350,000 motorcycles in 2006, about 230,000 bikes in 2011 and is on track to sell about 220,000 motorcycles this year. At the company’s peak six years ago, most new Harley’s sold in America were financed with home equity loans. Now many of those mortgages are either underwater or have been foreclosed. Harley has adjusted to the impoverishment of its traditional customers by concentrating on marketing to women, ethnic and racial minorities and young people, although Wandell told the Journal that this years sales “partly reflect ‘pent-up demand’ as some customers who held off during the recession finally returned to the market.”

Harley-Davidson’s net profit margin is now almost 16 percent. The company’s profit margin was about 12.5 percent when Wandell took over. The margins are notable. By way of contrast grocery stores have an average profit margin of about one percent. Movie studios average profit margins of about 10 percent. Service businesses usually have higher margins than manufacturers and other hard businesses. Physicians enjoy profits of about 13 percent. Law firms average profit margins in the Harley-Davidson range – around 17 percent.

skip to main |

skip to sidebar

Bill & Annie

Art Hall & Rusty

NUFF SAID.......

OOHRAH

ONCE A MARINE,ALWAYS A MARINE

GIVING BACK

MOUNT SOLEDAD

BIKINI BIKE WASH AT SWEETWATER

FRIENDS

BILL,WILLIE G, PHILIP

GOOD FRIENDS

hanging out

brothers

GOOD FRIENDS

Good Friends

Hanging Out

Bill & Annie

Art Hall & Rusty

Art Hall & Rusty

NUFF SAID.......

NUFF SAID......

Mount Soledad

BALBOA NAVAL HOSPITAL

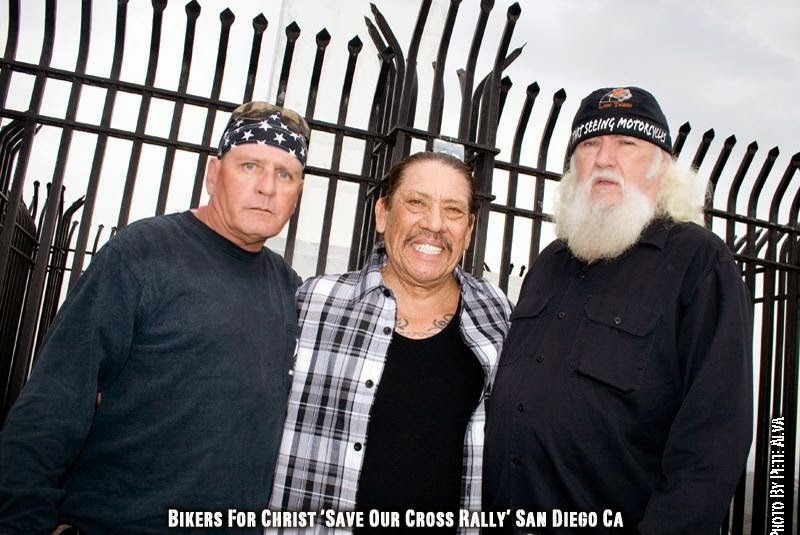

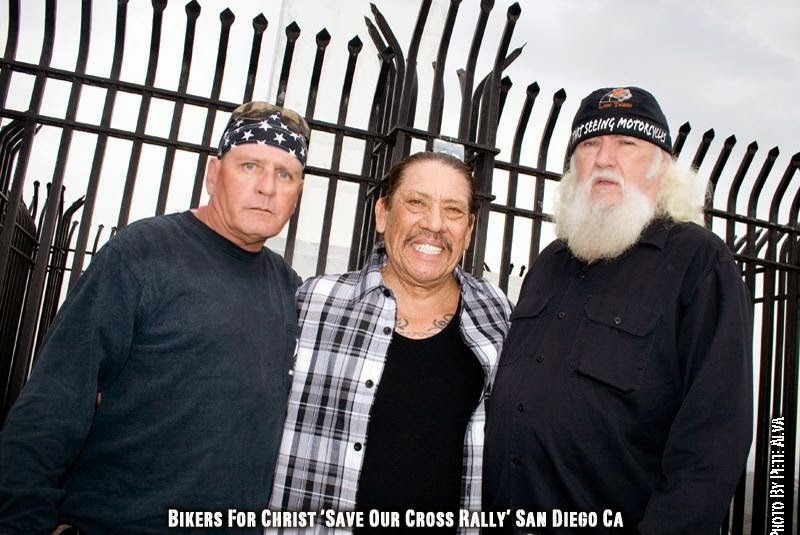

RUSTY DANNY

ANNIE KO PHILIP

PHILIP & ANNIE

OUT & ABOUT

OOHRAH...

OOHRAH

ONCE A MARINE,ALWAYS A MARINE

ONCE A MARINE,ALWAYS A MARINE

American Soldier Network GIVING BACK

GIVING BACK

CATHY & BILL

PHILIP & DANNY & BILL

MOUNT SOLEDAD

bills today

EMILIO & PHILIP

WATER & POWER

WATER & POWER

bootride2013

BIKINI BIKE WASH AT SWEETWATER

ILLUSION OPEN HOUSE

FRIENDS

GOOD FRIENDS

BILL,WILLIE G, PHILIP

GOOD FRIENDS

GOOD FRIENDS

Friends

- http://www.ehlinelaw.com/losangeles-motorcycleaccidentattorneys/

- Scotty westcoast-tbars.com

- Ashby C. Sorensen

- americansoldiernetwork.org

- blogtalkradio.com/hermis-live

- davidlabrava.com

- emiliorivera.com/

- http://kandymankustompaint.com

- http://pipelinept.com/

- http://womenmotorcyclist.com

- http://www.ehlinelaw.com

- https://ammo.com/

- SAN DIEGO CUSTOMS

- www.biggshd.com

- www.bighousecrew.net

- www.bikersinformationguide.com

- www.boltofca.org

- www.boltusa.org

- www.espinozasleather.com

- www.illusionmotorcycles.com

- www.kennedyscollateral.com

- www.kennedyscustomcycles.com

- www.listerinsurance.com

- www.sweetwaterharley.com

Hanging out

hanging out

Good Friends

brothers

GOOD FRIENDS

EMILIO & SCREWDRIVER

GOOD FRIENDS

Danny Trejo & Screwdriver

Good Friends

Navigation

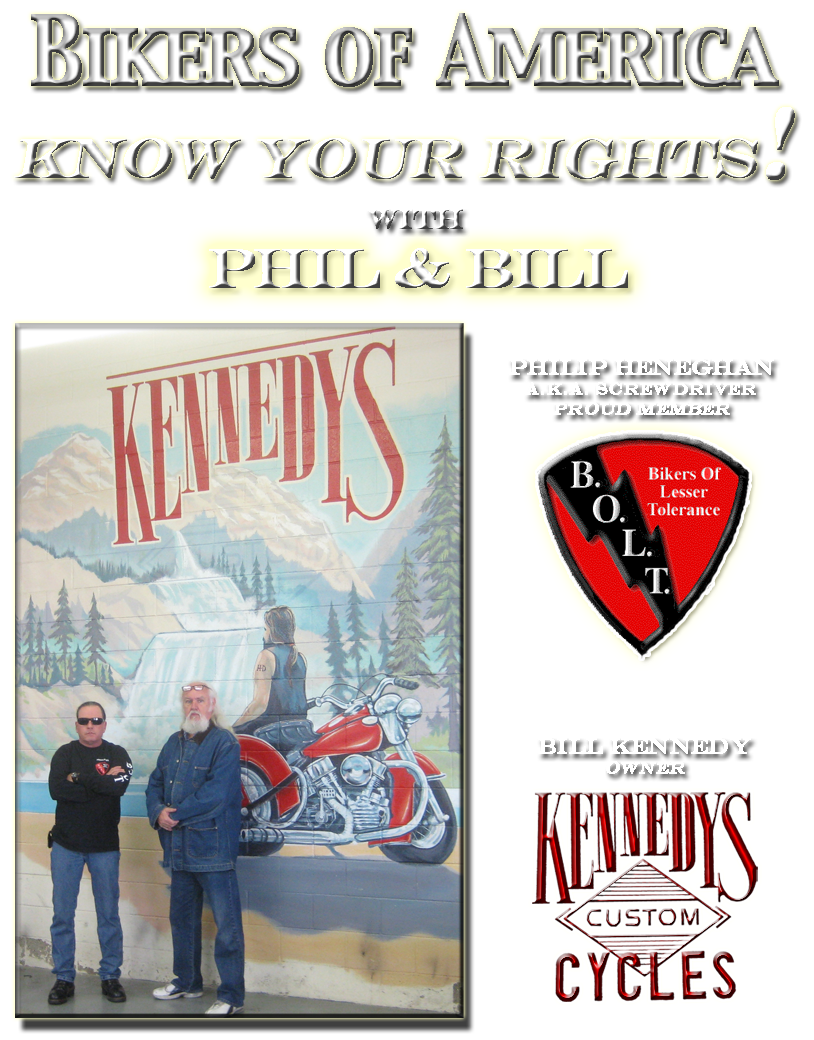

Welcome to Bikers of America, Know Your Rights!

“THE BIKERS OF AMERICA, THE PHIL and BILL SHOW”,

A HARDCORE BIKER RIGHTS SHOW THAT HITS LIKE A BORED AND STROKED BIG TWIN!

ON LIVE TUESDAY'S & THURDAY'S AT 6 PM P.S.T.

9 PM E.S.T.

CATCH LIVE AND ARCHIVED SHOWS

FREE OF CHARGE AT...

BlogTalkRadio.com/BikersOfAmerica.

Two ways to listen on Tuesday & Thursday

1. Call in number - (347) 826-7753 ...

Listen live right from your phone!

2. Stream us live on your computer: http://www.blogtalkradio.com/bikersofamerica.

A HARDCORE BIKER RIGHTS SHOW THAT HITS LIKE A BORED AND STROKED BIG TWIN!

ON LIVE TUESDAY'S & THURDAY'S AT 6 PM P.S.T.

9 PM E.S.T.

CATCH LIVE AND ARCHIVED SHOWS

FREE OF CHARGE AT...

BlogTalkRadio.com/BikersOfAmerica.

Two ways to listen on Tuesday & Thursday

1. Call in number - (347) 826-7753 ...

Listen live right from your phone!

2. Stream us live on your computer: http://www.blogtalkradio.com/bikersofamerica.

Good Times

Hanging Out

Key Words

- about (3)

- contact (1)

- TENNESSEE AND THUNDER ON THE MOUNTAIN (1)

- thinking (1)

- upcoming shows (2)

Blog Archive

-

▼

2012

(4602)

-

▼

September

(251)

- Montana - Butte supervisors told motorcycle riders...

- South Carolina - Bifield Declines Pro Se

- 'Lost in Coney Island'—remake of'The Warriors'—pla...

- Beat it, WNBA — Bikini Basketball League is coming...

- NUFF SAID.....

- NEBRASKA - Motorcycle-helmet enforcement effort ends

- MARYLAND - Scooter helmet law to take effect Law t...

- PIC OF THE DAY..

- Combat vet sues over Wyoming traffic stop.

- Sons Of Anarchy Crime Wave Continues

- NEVEDA - Sparks Grand Jury Testimony

- USA - Four-gallon minimum fuel mandate: EPA fails ...

- PIC OF THE DAY..

- Babe`s of the DAY..... This is 18 and older. Rest...

- ILLINOIS:

- NEVEDA - FBI, DEA agents handling Reno cases durin...

- Austin Police Revealing Pattern of Abuse Against C...

- Babe`s of the DAY..... This is 18 and older. Rest...

- PIC OF THE DAY

- 'Sons of Anarchy': A Major Death Shakes Up SAMCRO

- Houston Police Officers Used Ticket Scheme to Earn...

- NEW ZEALAND - Faced with 11 years in jail, gang me...

- CANADA - More judges need to recognize power of th...

- DENMARK - Police arrest Hells Angels members for a...

- NUFF SAID..

- Babe`s of the DAY..... This is 18 and older. Rest...

- PIC OF THE DAY

- CA - Missing Mongol

- MASS - Marine William F "Bill" O'Mahoney Sr. Funer...

- USA - Justice Dept. Must Turn Over Full Gang Records

- Brian Brewer Is Dying

- CA - FRENCH VALLEY: Trial for Hells Angels member ...

- AUSTRALIA - $1.2M OF ICE FOUND BY ANTI-BIKIE POLICE

- AUSTRALIA - Bikie presence leads to early pub closure

- Nevada Helmet Law (NRS 486.231)

- CA - Calif. gov. signs 18 bills that benefit veterans

- USA - We have been invaded...Buy ammo and buy ammo...

- Three-Star General: Muslim Brotherhood Has Infiltr...

- Babe`s of the DAY..... This is 18 and older. Rest...

- PIC OF THE DAY

- Keep Little Scotty Free: Defense Fund

- 2012 Las Vegas BikeFest Starts This Thursday Septe...

- AUSTRALIA - Bandidos national run staying at Oaks ...

- DENMARK - Latest biker gang violence was internal,...

- ARIZONA - Truck driver convicted in deadly motorcy...

- FLORIDA - US Court of Appeals upholds right of tol...

- Lean, Mean, Robotic Harley

- Bikers protest EU vehicle-inspection plan

- CA - Los Angeles Fire Department tries out a motor...

- PIC OF THE DAY..

- sacremento toy run

- Protest group's boot camp ensures no future shorta...

- NUFF SAID..

- USMC - Commandant: No issues with gay and lesbian ...

- MILITARY: Remembering Inchon

- US Navy's new floating base gets a workout in Gulf

- CA - Pressure mounting in Vallejo police fatal sho...

- HOUSTON,TX - Cop kills pen wielding double amputee

- Pediatric Brain Tumor Foundation's Ride for Kids o...

- Given the Rochester, NY Police department’s Long H...

- This is why Californians are confused...

- PIC OF THE DAY..

- PIC OF THE DAY

- USA - Biker rally turns ugly (Rosco and cleetus at...

- EUROPE - Bikers protest EU vehicle-inspection plan

- USA - Motorcycle Noise Pollution Runs Roughshod Ov...

- Babe`s of the DAY..... This is 18 and older. Rest...

- PIC OF THE DAY..

- Booze and bullets? Georgia firing range gets OK to...

- The Working Personality of Police Officers

- SAN DIEGO, CA - Libertopia 2012

- USA - A Wiretapping Double Standard: Machines vs. ...

- North Carolina Sheriff Targeted Latinos; Federal I...

- FLORIDA - Bikini dancer's mother fears biker gang ...

- CANADA - Pitt Meadows seeks to ban bikers from bars

- AUSTRALIA - Police raid biker gaxxx strongholds

- AUSTRAILA - Bikies Arrested

- CANADA - Hall, police met alone, court records reveal

- CANADA - 3 biker gaxxx members charged with threat...

- Babe of the Week, Ciao

- GUSTAVO VASQUEZ, AWESOME WORK CHECK IT OUT..

- Babe`s of the DAY..... This is 18 and older. Rest...

- Muslim Extremist/Communist Residing In The White H...

- Pirates' 'Hells Angels,' 'Navy SEALs' minor league...

- Do you have one of America's most dangerous jobs?

- PIC OF THE DAY

- Homeless Worker

- Today

- Extra police, colors ban at Nevada motorcycle rally

- Helmet poll for Rhode Island

- Sunday Motorcycle crackdown Stockton CA

- PIC OF THE DAY - NUFF SAID

- AUSTRALIA - On your bike... Motorbike riders may b...

- Babe`s of the DAY..... This is 18 and older. Rest...

- PIC OF THE DAY

- Babe`s of the DAY..... This is 18 and older. Rest...

- NEVEDA - No Colors, New Venues, A Safer Street Vib...

- EUROPE - Seven Members of Outlaws Motorcycle Club ...

- EUROPE - Hells Angels sentenced over string of off...

- USA - Lawyer here fighting U.S. ban on visas for H...

-

▼

September

(251)

Bikers of America, Know Your Rights!... Brought to you by Phil and Bill

Philip, a.k.a Screwdriver, is a proud member of Bikers of Lesser Tolerance, and the Left Coast Rep

of B.A.D (Bikers Against Discrimination) along with Bill is a biker rights activist and also a B.A.D Rep, as well, owner of Kennedy's Custom Cycles